Topic outline

-

The missions of the mechanical manufacturing engineer are deployed from the analysis to the implementation of new systems.

His mission is to create mechanical systems or parts, based on his analyses of the mechanical needs of a company. He supervises both the manufacturing and assembly as well as the maintenance of mechanical systems, and therefore manages the technicians under his supervision, while ensuring compliance with safety measures. https://www.junia.com/fr/fiches-metiers/ingenieur-en-fabrication-mecanique/

-

- Course teacher: AMOR Noureddine / MCB

- Contact :

Mail : noureddine.omar@gmail.com n.amor@univ-djelfa.dz

- Faculty: Science and technology FST.

- Department: Mechanical Engineering

-

- Target audience: Second year engineer Mechanical Engineering

- Semester: 3

- Teaching unit: UEF 3.2

- Course : Mechanical Engineering

- Global schedule : 67h30.

- Course: 1h30 + Tutorials 1h30 + PW 1h30

- Credit: 5

- Coefficient: 3

- Assessment mode: Exam 60% + 40%(20% T + 20% PW)

-

The aim of this course is to help students acquire as much information as possible in order to assimilate the phenomenon of metal cutting as well as the structure of machine tools.

The objectives according to the course elements can be cited as follows:

- Know the cutting materials and their uses.

- Know and understand the geometry of cutting tools.

- Understand the chip formation mechanism.

- Knowledge and calculation of cutting forces.

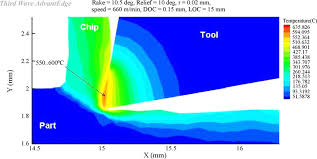

- Understand the heating phenomenon during metal cutting.

- Analysis of damage to cutting tools and determination of service life.

- Make the best choice of cutting parameters.

- Understand the structure of a machine tool.

-

Recommended prior knowledge:

Course:

- Basic Technology

- Materials Science

-

I- Theory of metal cutting

1.0 Introduction

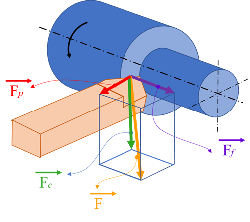

1.4 Cutting efforts

1.5 Heating (Cutting temperature)

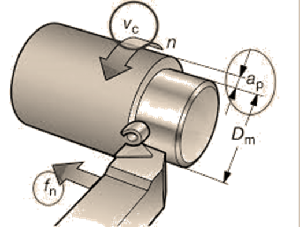

1.7 Methodology for choosing cutting parameters

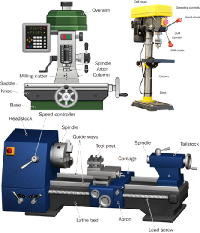

II- Machine Tool Technologies

2.2 Characterization of a machine tool (Main components)

- Spindle

- Frame

- Slides

2.3 Cinematic chains

- Movement transmission mechanisms

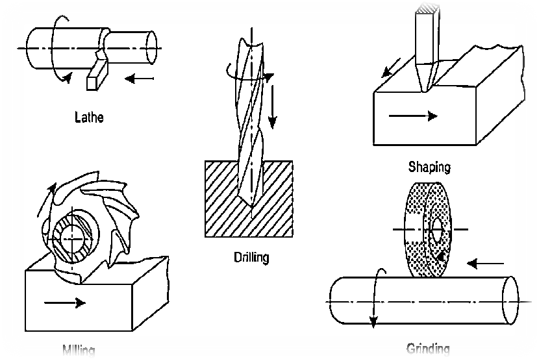

- Lathes, planers and vice-filers, Drills, milling machines, Broaching machines, Cylindrical and surface grinders, etc

-

-

Mechanical manufacturing is a sector that involves skilled workers whose job is to design, manufacture, modify, repair or assemble various parts, tools, accessories and metal products. Motors, gears, pumps and compressors are examples of products.

-

Cutting tools are tools used to remove material from a workpiece in the form of chips. They are used in a wide range of manufacturing and machining processes, such as drilling, milling, turning, and grinding. The selection of cutting tools is crucial to the efficiency and quality of the machining process. There are many different types of cutting tools available, each with their own unique characteristics and uses.

https://www.palbit.pt/en/introduction-to-cutting-tools

https://www.mecholic.com/2016/02/what-is-cutting-tools-introduction.html

-

Cutting Tool Geometries

Cutting tools for metal cutting have many shapes, each of which are described by their angles or geometries. Every one of these tool shapes have a specific purpose in metalcutting. The primary machining goal is to achieve the most efficient separation of chips from the workpiece. For this reason, the selection of the right cutting tool geometry is critical.

https://www.sme.org/technologies/manufacturing-topics/cutting-tool-geometries/

https://dikshyabhattarai.com.np/single-point-cutting

-

-